If you’re starting your diamond engagement ring research in 2022, you’ll stroll onto a landscape vastly different from even a decade ago.

Laboratory grown diamonds have become a viable recommendation and in turn choice for many couples during their search for the perfect engagement ring, or any fine diamond jewellery for that matter.

We’re far from a milieu where laboratory diamonds dominate the fine jewellery world, but they have a lot going for them, and we’ll be seeing a lot more of them in the coming years.

Let’s explore their origin story, and how this compares to that of mined diamonds.

Laboratory grown diamonds in a nutshell

Lab-grown diamonds (also referred to as laboratory-made diamonds, lab diamonds, man-made diamonds, cultured diamonds) are as real as any diamond that has ever been mined from the Earth.

Laboratory diamonds are made in controlled laboratories that mimic and greatly expedite the natural diamond formation process from millions of years to months.

Using the same ingredients as the Earth’s mantle (carbon) this process yields true and real diamonds with their characteristic crystal structure, sparkle, fire and durability.

They’re 100% real diamonds.

How are diamonds made?

Mother earth has used the same recipe for millions of years:

Natural occurring carbon + extreme pressure + high heat = crystallised carbon (diamond).

Modern science holds that diamonds were formed at least hundreds of millions of years ago at a depth of up to 150kms under the Earths surface.

Carbon found itself in a tight spot in temperatures of up to 1100’C and pressure as high as 50 000 atmospheres.

The carbon crystallised into diamonds and was then moved towards the earth’s surface through volcanic activity over aeons.

First To The Party: High Pressure, High Temperature (HPHT)

The race to create a diamond in a laboratory environment started in the early 1940s, but efforts were disrupted by the war.

In 1958 scientists at General Electric took first prize by successfully creating a diamond in a controlled environment by crystalising carbon through immense pressure and temperature in a chamber.

And in what I assume was a short meeting, GE named the process: “High Pressure, High Temperature” (HPHT).

In the HPHT process, a tiny diamond (seed) is placed in the centre of a chamber filled with carbon. Using pressure up to 100 000 atmospheres, and temperatures reaching 2000’C celsius, the carbon melts and crystalises around the seed; thereby growing it.

Using this method, diamonds of a useable size can be grown in a few short months.

*Diamonds after the HPHT growing process.

Fun Fact; the current world record for the largest lab-grown diamond is a whopping 155cts! By ze Germans, of course.

And then; Chemical Vapour Deposition (CVD)

A few decades later the CVD process was perfected and offered a second method for crystallising carbon into diamonds in a laboratory.

A small seed diamond (often formed by HPHT) is placed into a chamber that’s filled with a carbon-rich gas.

The gas is then ionised into a plasma using technology similar to lasers and microwaves. This essentially breaks down the molecular bond of the gas, and when heated to around 700’C pure carbon starts raining down in the chamber, crystalising layer by layer on top of the seed diamond.

Although the CVD process seems more technologically advanced, the HPHT process is still seen as the best method to grow gem-quality diamonds for high-end jewellery.

Further Processing into the gems we love and treasure.

Regardless of how the carbon was crystalised, the rest of the manufacturing cycle is identical.

First Step: Planning

Rough diamonds, whether mined or lab-created come in all shapes and sizes.

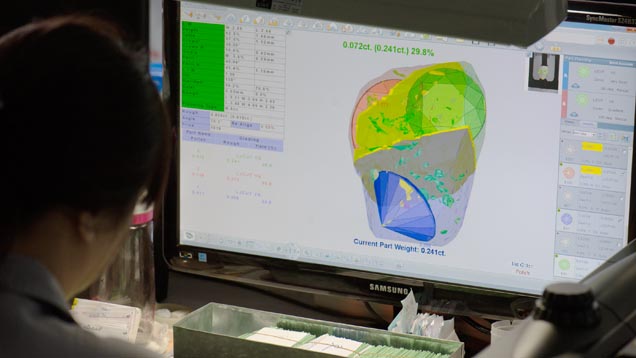

Rough diamonds are 3D scanned and using modern imaging technologies technicians finely determine what the best fit of shape and size is to the rough material.

*A Rough diamond being analysed with a Sarin machine.

The basic shape is marked by lasers and the diamond is moved on to the next step of manufacturing.

Second Step: Cutting and Polishing.

The rough diamond is then cut by even stronger strong lasers using the guidelines marked during planning.

After the diamond is lasered into its blueprint, they’re transferred to a diamond cutter who then meticulously finishes and polishes the diamond into its shiny final state.

Final Step; Grading

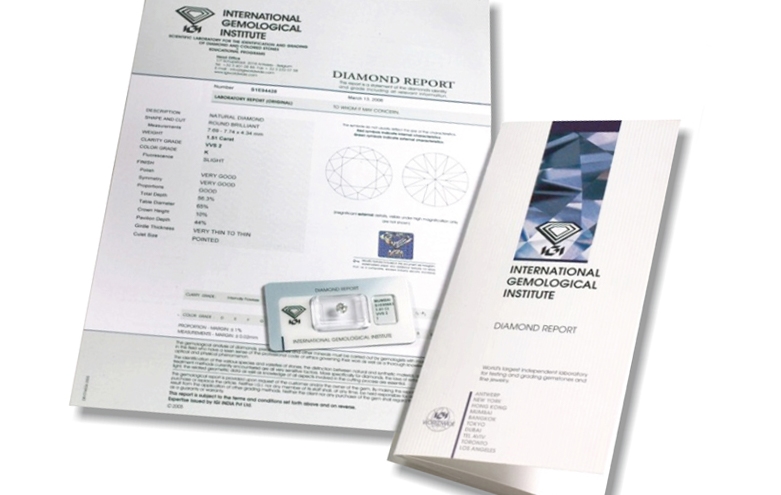

Once the diamonds are all polished up, they’re individually packed and sent off to independent diamond grading laboratories.

Here, gemologists take great care in grading each diamond according to its colour, clarity and size.

The newly graded diamonds are repackaged into neat grading certificates indicating all the diamond’s unique specifications and returned to the manufacturer who then distributes them down his sales chain.

The most trusted laboratory for grading mined diamonds is the GIA.

Although the GIA also grades laboratory-grown diamonds, the IGI seems to have taken the lead in this segment.

IGI certification is by no means inferior, but it is materially more economical than the GIA route. With laboratory diamonds trading at up to 60% less than mined diamonds, more affordable grading was a good fit.

In our experience, the grades issues by IGI easily hold up to the GIA standards.

Both are trustworthy, consistent, internationally regarded and recognised.

Same, same?

The line separating laboratory-made diamonds and mined diamonds is paper-thin.

Apart from how natural is crystalised, the processing is identical.

The future is lab-grown diamonds is bright.

It’s absolutely worth looking into for your dream engagement ring.

If you have any questions, you can find me at johan@poggenpoel.com

And here is some interesting further reading;

- The 4C’s of Laboratory Grown Diamonds

- Laboratory Diamond Buying Guide (2022)

- Are Laboratory Grown Diamonds A Good Investment

Take Care

Johan Poggenpoel

Co-Founder, Poggenpoel Jewellers

www.poggenpoel.com